The utilization of non-woven fabric in medical apparatus and equipment. Product information 17/04/2023

In the English language, nonwoven fabric is referred to as “nonwoven.” This appellation accurately mirrors the essence of this fabric, for it is not crafted by conventional weaving or knitting methods, but instead, it takes form from interconnected sheets with a grid-like or panel structure. In this exposition, we shall delve into the applications of nonwoven fabric in the realm of medical equipment.

These sheets are bonded together using Polypropylene particles (synthetic plastic), which are then amalgamated into fibers via mechanical or thermal means. Subsequently, these fiber strands are pierced using chemical agents or mechanical apparatus to unite them, thereby creating lightweight fabric sheets that offer a smooth, velvety texture, delivering comfort to the end user.

As a global manufacturing facility, Rạng Đông Healthcare is poised to acquaint its esteemed clientele with the advantages of nonwoven fabric, which include elasticity, durability, water resistance, antimicrobial properties, ease of production, cost-effectiveness, and reusability.

Hence, it finds wide-ranging utilization in everyday consumer products such as toilet paper, hand towels, as well as medical products such as masks, bandages, medical towels, and other medical paraphernalia. Furthermore, it is employed in various other industries like packaging, food and beverages, automotive, and aerospace.

The utilization of non-woven fabric in medical apparatus.

The attributes and characteristics of non-woven fabric

Applications of nonwoven fabric in medical equipment, along with its features and attributes, encompass the following:

- Absorbency and Waterproof Characteristics: Its ability to resist water and other fluids helps shield products or surfaces beneath it from moisture-induced damage.

- Antibacterial Properties: The fabric’s intrinsic antibacterial attributes deter the growth of bacteria and mold, thereby safeguarding the health of users.

- Elasticity and Durability: Nonwoven fabric exhibits impressive elasticity and high durability, making it suitable for medical garments, footwear, and sports-related products.

- Ease of Production and Cost-Efficiency: It can be manufactured swiftly and efficiently, tailored to customer preferences in terms of color and size, at a lower cost compared to traditional fabric varieties.

- Reusability: It can be reused multiple times, reducing waste and minimizing environmental impact.

The indispensability of non-woven fabric in medical equipment

The imperative role of nonwoven fabric in medical equipment cannot be overstated. Its applications encompass:

Protective Gear: Nonwoven fabric is employed in the production of various medical protective gear, including masks, coats, aprons, stockings, caps, gloves, and protective eyewear, effectively shielding medical personnel and patients from potentially harmful fluids and particles.

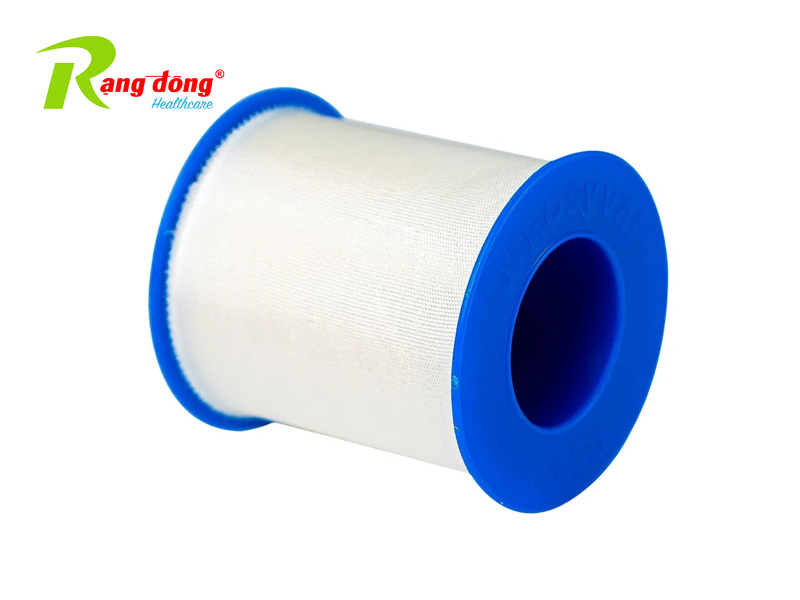

Medical Supplies: Nonwoven fabric is used in the production of medical supplies like bandages, adhesive tapes, pads, and chest wraps. Its absorbent and antibacterial properties ensure the safety and effectiveness of these products.

Medical Devices: Nonwoven fabric is instrumental in the manufacture of medical devices such as hospital mattresses, surgical bed linen, medical adhesive tapes, and mattress underpads. Its elasticity and high durability make it a popular choice for these products.

Consequently, nonwoven fabric assumes a pivotal role in the realm of medical equipment, safeguarding the health of medical personnel and patients while ensuring the efficiency and safety of medical products.

The advantages of employing non-woven fabric in medical apparatus

Absorbency and antibacterial

Benefits of employing nonwoven fabric in medical equipment include its absorbent and antibacterial properties, which enhance product quality and bestow numerous advantages upon users, such as health protection, cost savings, and ease of maintenance.

Comfort for patients

Patient comfort is another key facet, as nonwoven fabric does not provoke skin irritation, offers breathability, and is lightweight and pliable. This, in turn, facilitates patient mobility and daily activities during medical treatment.

Ability to reuse and recycle

Moreover, nonwoven fabric’s capacity for reuse and recycling in diverse applications underscores its environmental benefits, diminishing waste generation and conserving resources, all while reducing environmental impact.

Note when using non-woven fabric in medical devices

Requirements for quality and safety

Noteworthy considerations when using nonwoven fabric in medical equipment involve quality and safety prerequisites. Adherence to product regulations and standards, rigorous monitoring of raw materials, periodic quality checks, and adherence to designated purposes are all essential for ensuring quality and safety.

Production and usage costs

Production and utilization costs for nonwoven fabric in medical equipment necessitate advanced technologies and modern equipment. Consequently, nonwoven fabric production costs tend to be higher compared to traditional fabric types.

Quality control procedures and product management

Quality control procedures and product management are crucial when utilizing nonwoven fabric in medical equipment to ensure product safety and efficacy. The following are some key points regarding quality control and product management:

- Selection of High-Quality Nonwoven Fabric: Choose nonwoven fabric with high quality and compliance with necessary medical standards.

- Regular Quality Inspections: Implement regular quality inspections.

- Production Process Control: Exercise control over the production process to ensure product consistency.

- Post-Market Surveillance: Monitor products after they enter the market to ensure compliance with user requirements.

Nonwoven fabric stands as an indispensable material in the production of medical equipment. Its usage has significantly enhanced the safety and efficiency of medical devices, playing a vital role in safeguarding human health.

Nonwoven fabric has become an irreplaceable component in the medical field, and its potential in this domain is substantial. Rạng Đông Healthcare foresees outstanding development in nonwoven fabric’s future, with myriad new applications and technical enhancements on the horizon.