The uses of SMMS non-woven fabric Product information 08/05/2023

With a team of engineers and experienced experts trained in Japan and the United States, and being a medical equipment manufacturing unit with 100% domestic capital, Rang Dong Healthcare Company is among the top 5 high-end medical equipment exporters in Vietnam. Rang Dong Healthcare Company is a reliable partner providing the best products in the Vietnamese and international markets.

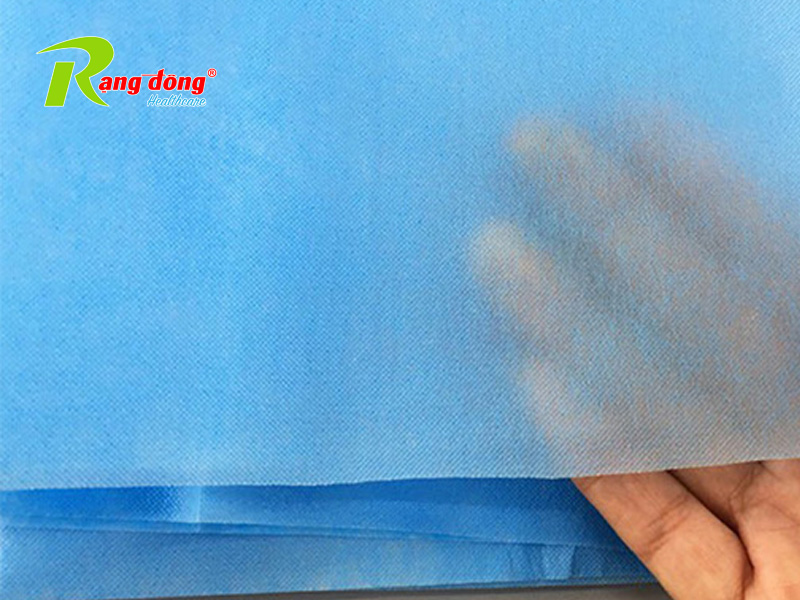

SMMS non-woven fabric is a multi-layered non-woven fabric produced by combining multiple layers of non-woven fabric with different structures.

The name SMMS comes from the abbreviations of the fabric layers, including Spunbond, Meltblown, Meltblown, and Spunbond.

Each fabric layer has different characteristics, and when combined, they create SMMS non-woven fabric with superior features such as waterproof, antibacterial, and high durability. SMMS non-woven fabric is commonly used in the medical and healthcare industry to manufacture medical products such as surgical gowns, wipes, and protective clothing.

| MODEL | Aspect Ratio | Production Capacity (tons/year) | Largest Product Width (mm) | Basis Weight (g/m2) | Fiber Fineness |

| SJ-TY-1600 | 30:1 | 1500 | 1600 | 10-200 | 2D-4D |

| SJ-TY-2400 | 2200 | 2400 | |||

| SJ-TY-3200 | 3200 | 3200 |

Additionally, it is also used in various industrial and civilian applications.

Production process of SMMS non-woven fabric

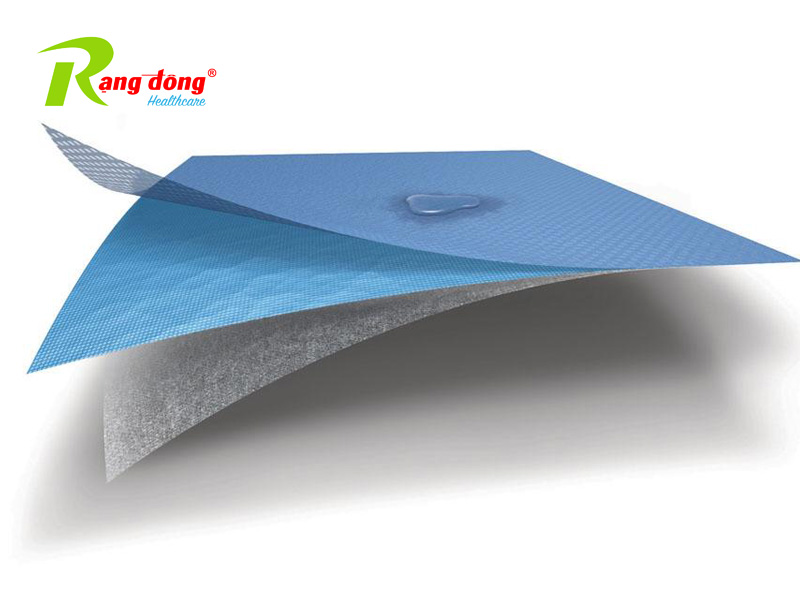

Spunbond Layer: Fibers are produced from plastic pellets fed into the extruder, drawn, and blown into fibers, then shaped into a Spunbond layer. This layer has properties of durability, elasticity, and good shaping.

First Meltblown Layer: This layer is produced by introducing plastic pellets into the extruder, blowing hot air to melt and spray fibers. The fibers fall onto the Spunbond surface, forming the first Meltblown layer. This layer has waterproof and antibacterial properties.

Second Meltblown Layer: Along with the production of the first Meltblown layer, the second layer is produced by introducing plastic pellets into the extruder and spraying fibers to form the second Meltblown layer. This layer also has waterproof and antibacterial properties.

Final Spunbond Layer: After completing the Spunbond and Meltblown layers, the final Spunbond layer is created by introducing fibers into the extruder and drawing and blowing to form the final Spunbond layer. This layer also has properties of durability, elasticity, and good shaping.

Layer Synthesis: The Spunbond and Meltblown layers are combined using heat sealing or ultrasonic bonding machines to create the final SMMS non-woven fabric.

After production, the SMMS non-woven fabric is quality tested to ensure it meets customer standards and requirements before entering the market.

Functions of SMMS non-woven fabric

Waterproof: With the Meltblown layer used to create the waterproof layer, SMMS non-woven fabric has the ability to resist water and other liquids.

Antibacterial: With the antibacterial properties of the Meltblown layer, it is used to manufacture medical products such as surgical gowns, wipes, and protective clothing to prevent the spread of bacteria and other disease-causing agents.

High Durability: With the Spunbond and Meltblown layers used to create the durable layer, SMMS non-woven fabric has high durability, can withstand pressure and tearing, and is not easily deformed.

Breathability: With the Spunbond layers used to create the breathable layer, it has good air permeability, making users feel more comfortable when using products made from this fabric.]

Easy to Clean: Easy to clean and reuse in certain cases, helping save costs and resources.

Applications of SMMS non-woven fabric in healthcare

SMMS non-woven fabric is widely used in the medical field because of its superior features such as antibacterial, waterproof, and breathable. Here are some applications of SMMS non-woven fabric in healthcare:

Surgical gowns: Manufacture surgical gowns to protect healthcare workers and patients from disease-causing agents such as bacteria and viruses.

Wipes: Manufacture various types of dry and wet wipes to ensure hygiene and prevent the spread of disease-causing agents.

Protective hats: Manufacture protective hats to protect the heads and faces of healthcare workers during surgical or patient care activities.

Lining and protective materials: Manufacture lining and protective materials, including pads and tapes, to protect wounds and reduce pain for patients.

Protective pillows and blankets: Manufacture products such as pillows and protective blankets to help patients stay warm and comfortable during treatment.

Applications of SMMS non-woven fabric in industry and consumer goods

In addition to the healthcare sector, SMMS non-woven fabric is also widely used in various industrial and consumer sectors, including:

- Paper manufacturing industry: Manufacture parts and accessories for machinery in the paper manufacturing industry.

- Automotive manufacturing industry: Manufacture accessories and parts in the automotive manufacturing industry, including air filters and oil filters.

- Bottled water production industry: Manufacture filters to filter impurities and bacteria in the production of bottled water.

- Food manufacturing industry: Manufacture filters to filter impurities and bacteria in the food manufacturing process.

- Household goods manufacturing industry: Manufacture daily consumer products, including various types of wipes, bath towels, blankets, pillows, floor mats, and mattresses.

SMMS non-woven fabric is a multi-layered non-woven fabric made from synthetic fiber, including Spunbond and Meltblown layers. SMMS non-woven fabric is a versatile fabric with many applications in different fields. With its antibacterial, absorbent, heat-resistant, waterproof, and high durability properties, SMMS non-woven fabric is becoming an essential and important material in our daily lives.