The applications of non-woven fabric with PE film in the medical field Product information 09/06/2023

Rang Dong Healthcare constantly improves manufacturing technology, producing advanced and diverse non-woven fabric with PE film products to meet stringent requirements in the medical field. The company’s commitment lies in providing high-quality, safe, and hygienic products, contributing to enhancing healthcare quality and protecting community health.

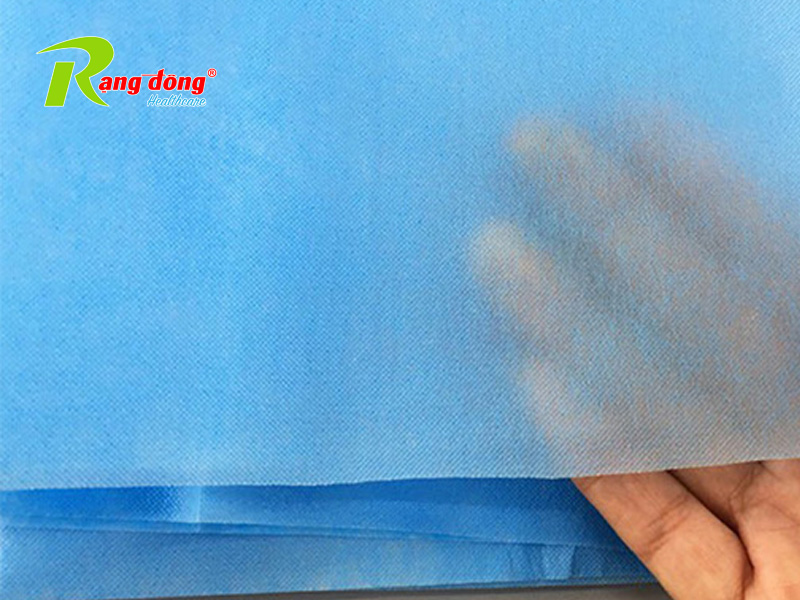

Non-woven fabric with PE film is a type formed by combining non-woven fibers and a polyethylene film layer on the surface. Non-woven fabric is a production technology that doesn’t involve weaving or knitting but uses cotton fibers, plastic fibers, or other synthetic fibers to create a fabric structure by pressing, bonding, or joining them together.

The polyethylene film is bonded to the non-woven fabric to provide features like water resistance, moisture resistance, and prevention of penetration by liquids, bacteria, and viruses. The PE film layer prevents liquid intrusion, ensuring safety and hygiene in medical applications. Non-woven fabric with PE film is often soft, durable, and adaptable to diverse medical applications such as protective clothing, air filtration, equipment, medical materials, and medical packaging.

Advantages of non-woven fabric with PE film in the medical field

- Waterproof: The PE film layer prevents water leakage, inhibits the infiltration of liquids, bacterial environments, and viruses, safeguarding users and the surrounding environment.

- Moisture resistance: Despite being waterproof, non-woven fabric with PE film allows air and moisture circulation, ensuring breathability and moisture release, providing comfort and limiting moisture accumulation.

- Anti-penetration capability: With the PE film layer, non-woven fabric can prevent the penetration of bacteria, viruses, and liquids that may cause infection, protecting users from infection risks.

- Durability and softness: Non-woven fabric with PE film is often highly durable, withstands mechanical impacts and stretching without tearing or deformation, ensuring safety and reliability in use. Additionally, it has relative softness, providing comfort when in contact with the skin.

- Flexibility and diverse applications: Non-woven fabric with PE film adapts to various medical applications such as protective clothing, air filtration, equipment, medical materials, and medical packaging.

Applications of non-woven fabric with PE film in the medical field

Non-woven fabric with PE film in medical protective clothing

Non-woven fabric with PE film is widely used in medical protective clothing due to its advantages. Here are some common applications:

- Medical protective clothing: Manufacturing medical protective clothing, ensuring water resistance and preventing the intrusion of potentially infectious liquids. This type of medical protective clothing is often used in healthcare settings to protect healthcare workers from exposure to hazardous liquids.

- Medical protective hats: Manufacturing medical protective hats. These hats protect the head and hair of healthcare workers from liquids that may cause infection, ensuring safety in medical environments.

- Medical protective caps: Manufacturing medical protective caps. These caps protect the face and eyes of healthcare workers from liquids, bacteria, and viruses during work.

Non-woven fabric with PE film in medical protective clothing not only provides waterproof properties but also ensures safety and hygiene for healthcare workers. It plays a crucial role in protecting health and reducing the risk of infection in medical environments.

Non-woven fabric with PE film in medical air filtration

Non-woven fabric with PE film also has significant applications in medical air filtration. Here are some common applications:

- Medical face masks: Manufacturing medical face masks. The PE film layer prevents bacteria, viruses, and fine particles from entering the mask, protecting users from harmful agents that may be present in the air.

- Medical air filters: Non-woven fabric with PE film is used in medical air filters. These filters can remove pollutants, bacteria, viruses, and fine particles from the air, ensuring that the air inhaled during medical treatment is clean and safe.

- Bacterial filters: Manufacturing bacterial filters in healthcare. These filters help eliminate and prevent the growth of bacteria in medical environments, ensuring hygiene and safety.

These applications of non-woven fabric with PE film in medical air filtration play a crucial role in protecting the health of users, limiting infections, and ensuring that the air in medical environments is clean and safe.

Non-woven fabric with PE film in medical equipment

Non-woven fabric with PE film has many applications in medical equipment. Here are some common applications:

- Medical tape: Manufacturing medical tape. This tape has waterproof properties, protecting wounds from bacteria and infectious liquids. It also has high durability and strong adhesion, ensuring stability and firmness during use.

- Medical gloves: Medical gloves are often made from non-woven fabric with PE film to ensure waterproof and protect users from bacteria and infectious liquids. These gloves are usually highly durable, have a snug fit, and provide a comfortable feel during use.

- Medical sleeves: Manufacturing medical sleeves. These sleeves have waterproof and anti-penetration properties, protecting users and the environment from liquids and infectious agents. They also have high durability and suitable softness to ensure flexibility during use.

With its waterproof properties and the ability to prevent bacteria and infectious liquids, non-woven fabric with PE film in medical equipment plays a crucial role in protecting users and the environment from infection risks and diseases.

Non-woven fabric with PE film in medical materials

The applications of non-woven fabric with PE film in medical materials are diverse and essential. Here are some examples of key applications:

- Medical pillows: Non-woven fabric with PE film is used to create covers for medical pillows. The waterproof and moisture-resistant properties of the fabric help protect pillows from water, liquids, and bacterial contamination. Additionally, non-woven fabric provides softness and breathability, ensuring comfort for users.

- Medical mattresses: Non-woven fabric with PE film is used in the production of medical mattresses. The PE film layer prevents water penetration and protects the mattress from bacterial contamination and liquids. Moreover, non-woven fabric has anti-static and anti-mold properties, creating a safe and hygienic environment for patients.

- Medical bandages: Non-woven fabric with PE film is used to manufacture medical bandages. With its waterproof characteristics, medical bandages have excellent moisture absorption and do not seep through. This ensures hygiene and protects wounds from bacterial contamination.

- Hospital covering materials: Non-woven fabric with PE film is also used as covering material for surfaces in hospitals, such as tables, chairs, beds, and medical equipment. The PE film layer prevents water leakage and protects surfaces from bacterial contamination and pollution. Additionally, it is easy to clean and disinfect.

Non-woven fabric with PE film in medical materials serves various purposes and is particularly crucial in the medical field. Rang Dong Healthcare’s products, including protective clothing, medical masks, bandages, medical gloves, and medical bags, are widely used in medical applications. Thanks to its antimicrobial properties, these products help protect users from bacteria, viruses, and liquid infiltration, contributing to a safe medical environment.

The future development potential of non-woven fabric with PE film is diverse and promising. Here are some significant potential aspects: Enhancing antimicrobial features, Integrating smart technology, Diversifying medical applications, Developing environmentally friendly non-woven fabric.