Choosing the Best Material for Non-Woven Fabric Coats Product information 21/09/2023

In the present era, the healthcare industry and health services in Vietnam and globally are experiencing robust growth. This growth has created new opportunities for products related to healthcare, leading to increased competition among providers. In this context, Rang Dong Healthcare Joint Stock Company has emerged with the motto “for the community’s health as a foundation.” They produce standard U.S. products, marking a significant advancement in Vietnam’s healthcare industry.

What is Non-Woven Fabric?

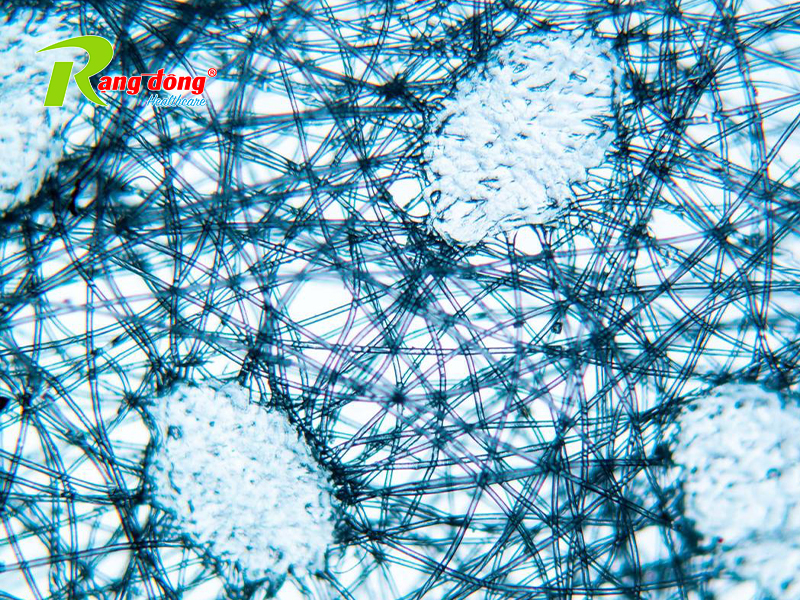

Before exploring how to choose the best materials for non-woven fabric coats, we need to understand what this type of fabric is. Non-woven fabric is a type that isn’t created through weaving or knitting methods. Instead, it is formed from Polypropylene particles—a synthetic plastic. Depending on its intended use, it can be combined with other recycled components. These materials are drawn into individual fibers and bonded together through chemical solvents or heat from modern machines to create lightweight, thin, soft, and highly durable fabric sheets. Because it doesn’t undergo the weaving process like other conventional fabrics, it is called non-woven fabric.

Characteristics of Non-Woven Fabric

- Non-Woven without Need for Weaving

One notable characteristic is that non-woven fabric forms based on the heat action of modern machines or solvents, binding individual fibers together without the need for weaving. This efficiently produces fabric products.

- Human and Environmentally Friendly

Non-woven fabric is trusted and used for creating high-safety products, posing no harm to human health and causing no adverse effects on the environment. This makes it a top choice in various applications.

Applications of Non-Woven Fabric

Non-woven fabric has diverse applications, from agriculture to healthcare and even in the fashion industry.

In agriculture:

- Insect Barrier: Used to create protective layers against insects and pests, safeguarding crops from their attacks.

- Antibacterial: Employed to cover agricultural products, protecting them from bacteria and mold.

In fashion:

- Underwear and Clothing: Commonly used in the production of underwear and clothing, ensuring comfort and safety for the wearer.

- Shopping Bags and Advertisement Bags: Utilized in manufacturing environmentally friendly shopping bags and promotional bags.

In labor protection:

- Protective Work Clothing: Preferred for producing labor protection clothing, ensuring safety for workers.

- Labor Gloves and Masks: Used to manufacture gloves and masks, protecting workers from harmful elements.

In healthcare:

- Isolation Gowns and Surgical Attire: Widely used in the production of medical products like isolation gowns and surgical attire to ensure safety and hygiene.

- Masks and Diapers for Children: Also used in making masks and diapers for children, especially in times of health crises and healthcare needs.

Technology and Equipment

The non-woven fabric production line typically uses polypropylene (PP) as the raw material. By utilizing the fiber stretching principle of chemical fibers, the threads are meshed through heat pressing machines to create the final product. This production process is entirely automated, from raw material input to the final product, reducing time and increasing production efficiency.

The non-woven fabric production line is designed to produce high-strength, flexible, non-toxic, antibacterial, and highly durable fabrics. These non-woven fabric products find extensive use in industries, agriculture, fashion, labor protection, and healthcare.

Non-woven fabric plays a crucial role in various fields due to its flexibility, safety, and high durability. Choosing the best material for non-woven fabric coats is a significant step to ensure the final product meets quality and performance standards.