The ability to withstand pressure and heat of the PP non-woven fabric laminated with PE Product information 08/11/2023

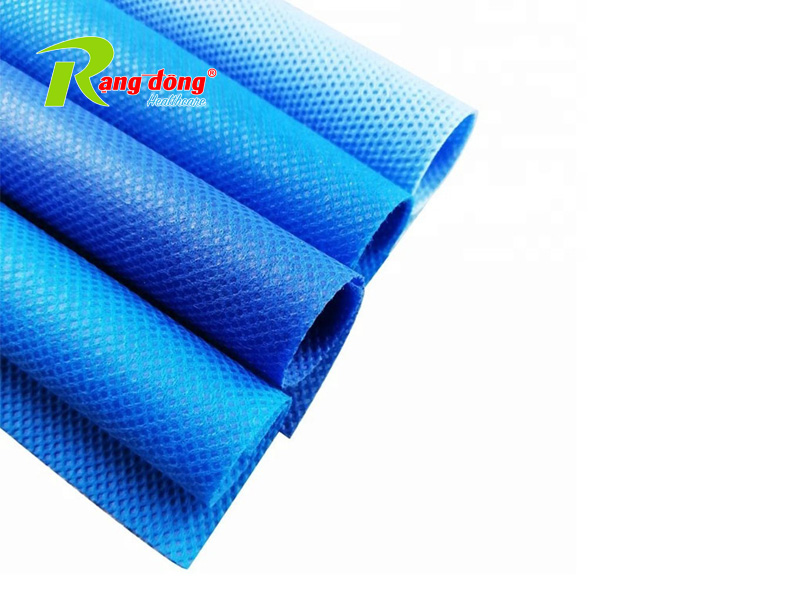

Non-woven PP/PE laminated film is a material made by laminating a polyethylene (PE) film on the surface of a non-woven PP fabric. Non-woven PP fabric is made from polypropylene fibers that are combined with each other using heat or pressure. PE film is a thermoplastic that is water-resistant, dust-proof, and has good tensile strength.

Structure and composition of non-woven PP/PE laminated film

Non-woven PP/PE laminated film has a three-layer structure:

- Non-woven PP layer: This layer provides strength and stiffness to the product.

- PE layer: This layer provides water resistance, dust resistance, and good tensile strength.

- Adhesive layer: This layer bonds the non-woven PP layer and the PE layer together.

Types of non-woven PP/PE laminated film

There are many different types of non-woven PP/PE laminated film, which are classified based on factors such as:

- Thickness of the non-woven PP layer

- Thickness of the PE layer

- Type of adhesive used

Tensile strength of non-woven PP/PE laminated film

The tensile strength of non-woven PP/PE laminated film depends on several factors, including:

- Thickness of the non-woven PP layer

- Thickness of the PE layer

- Type of adhesive used

- Testing method

The tensile strength of non-woven PP/PE laminated film is typically tested using the tensile test method. This method measures the force required to break the non-woven PP/PE laminated film.

Heat resistance of non-woven PP/PE laminated film

The heat resistance of non-woven PP/PE laminated film depends on several factors, including:

- Type of PE used

- Thickness of the PE layer

The heat resistance of non-woven PP/PE laminated film is typically tested using the melting point test or the heat distortion test.

Applications of non-woven PP/PE laminated film

Non-woven PP/PE laminated film has many applications in various fields, including:

- Medical: Non-woven PP/PE laminated film is used to produce face masks, medical protective gear, medical tape, etc.

- Industrial: Non-woven PP/PE laminated film is used to produce packaging, bags, waterproof membranes, etc.

- Agriculture: Non-woven PP/PE laminated film is used to cover the ground, protect crops, etc.

- Daily life: Non-woven PP/PE laminated film is used to produce

Non-woven PP/PE laminated film is a versatile material with many applications in various fields. Non-woven PP/PE laminated film has the advantages of high strength, water resistance, dust resistance, and good heat resistance, which can meet the needs of people in modern life.

Future application trends of non-woven PP/PE laminated film

Here are some trends in the application of non-woven PP/PE laminated film in the future:

- Medical: Non-woven PP/PE laminated film will be used to produce new medical products that have better protection for users and are more environmentally friendly.

- Industrial: Non-woven PP/PE laminated film will be used to produce new industrial products that are more resistant to harmful factors such as chemicals, impact, etc.

- Agriculture: Non-woven PP/PE laminated film will be used to produce new agricultural products that help increase crop yields and reduce environmental pollution.

- Daily life: Non-woven PP/PE laminated film will be used to produce new daily-use products that are more environmentally friendly and convenient for users.

With its outstanding advantages, non-woven PP/PE laminated film has the potential for strong development in the future.

Additional information

- Non-woven PP/PE laminated film is a sustainable material that can be recycled.

- Non-woven PP/PE laminated film is a cost-effective material that can be used in a variety of applications.

- Non-woven PP/PE laminated film is a versatile material that can be customized to meet the specific needs of each application.

I hope this translation is accurate and helpful. Let me know if you have any other questions.