PVC vs ABS: which plastic should you choose? Product information 14/11/2023

If you’re looking for a rigid, durable and low-cost plastic for your injection molded component, then either polyvinyl chloride (PVC) or acrylonitrile butadiene styrene (ABS) would be good thermoplastics to consider.

However, as raw materials they each have slightly different characteristics which make them suitable for particular use cases. This guide will explain the differences to help you select the right polymer for your component. It will cover:

What is PVC material?

PVC polymer is a crystalline thermoplastic. This means the molecular structure between its vinyl chloride monomers is regular and tightly bonded, giving the polymer its durable and rigid material characteristics. However, PVC can also be heated and remolded into new shapes thanks to its thermoplastic nature. The molding temperature of PVC is between 68°F and 140°F while it will melt between 338°F and 410°F.

As one of the world’s most widely used plastics, there are a range of PVC materials which have different qualities to the base polymer. These are created during the manufacturing processes by mixing the base PVC with specific additives. For example, adding plasticizers can help to soften the material to create a more flexible plastic while heat stabilizers can enhance PVC’s thermal properties.

What is PVC used for?

Pure PVC resin, PVC sheets or pellets have very specific characteristics that include:

- Great durability

- Shock, flame and inorganic chemical resistance

- Lightweight, hard and strong

- Good electrical insulator

- Versatility and cost-effectiveness

PVC properties make this polymer a popular choice in the medical, construction and automotive industries for products such as:

- Window profiles, frames and sills

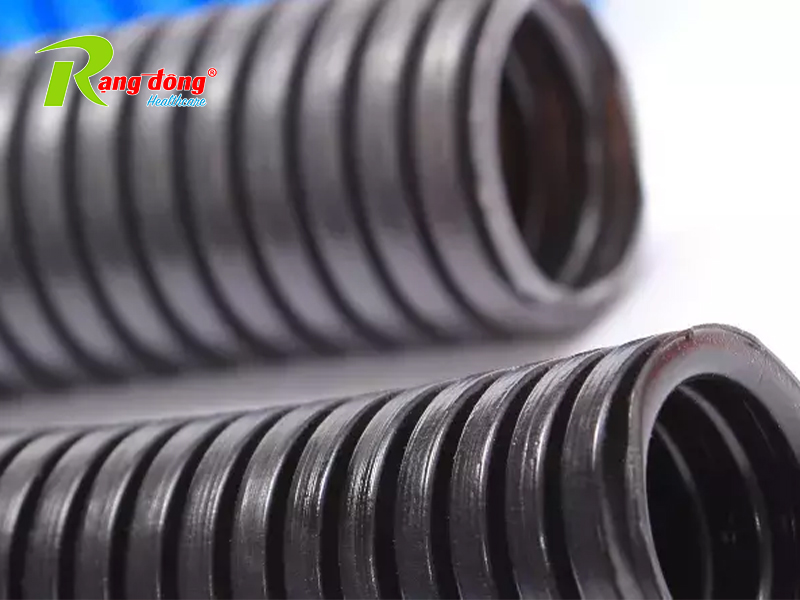

- PVC pipes

- Electrical wires and cables

- Roof and ceiling membranes

- PVC medical devices such as medical tubing, blood bags and masks

- Cable insulation and wire insulation

- Underbody coatings

- Car interior components

- Vehicle window sealing profiles

Plus, PVC products such as caps, plugs and electrical cable components, are durable and resistant in nature, making them an ideal choice for many applications.

What is ABS plastic?

ABS is a crystalline thermoplastic. A combination of the three chemicals: acrylonitrile, butadiene and styrene, ABS has strong molecular bonds and a rigid structure, making it tough and highly resistant in its most basic form.

Depending on specific use cases, other materials, such as heat or UV stabilizers can be added to ABS to further enhance or adapt its qualities. This versatility is what makes ABS a popular choice for a range of applications in the electronics, automotive, construction and medical industries.

Its thermoplastic qualities also mean ABS is used to create many injection-molded components, such as injection molded glides, inserts and snap-in components. With a mold temperature of between 113°F and 176°F and a melt temperature of 410°F and 500°F, it can be reformed into shape easily using a tightly controlled injection moulding process.

What is ABS plastic used for?

In its purest form, ABS has a range of desirable material characteristics, including:

- Good strength, rigidity and durability

- Resistance to chemicals, impacts and fire

- Good electrical insulation

- Easy to paint and glue to other materials

- A high gloss finish

This means ABS is commonly used in a range of use cases such as:

- Hydraulic and industrial pipework

- Automotive parts, such as dashboards and wheel covers

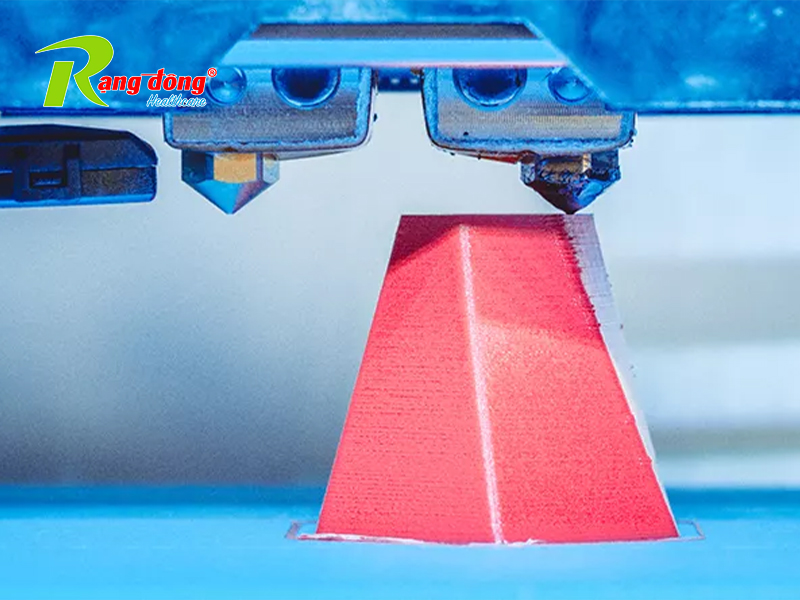

- 3D printed medical devices

- Household pipes and fittings

- Computer keyboard keys

- Household tools and vacuum products

How to recycle PVC and ABS plastic

Widely used across many common applications, the strong molecular structure of PVC and ABS makes them difficult to break down, process and reproduce in a usable form. However, they can both still be recycled by specialized processors:

PVC and ABS materials can be recycled in a number of ways:

- Manually removing any other materials and chemically stripping additives from the PVC or ABS material

- Cleaning and removing particulates or paints from the polymer.

- Remelting, remolding and, in some cases, grinding the plastic into reusable recycled materials such as pellets or sheets

Recycled PVC can be used in both rigid and flexible forms. Typically, it is remade into components for the construction, agriculture and manufacturing industries. Recycled ABS can be used for non-food-grade applications, including injection molded and 3D-printed components, such as pipes and fittings. It can also be used to create prototypes.

The intensive nature of recycling these polymers is important to keep in mind when choosing either ABS or PVC. Especially for businesses looking to minimize their environmental impact alongside their costs. Some injection molding manufacturers will be able to recommend and assist with the end-of-life processes of plastic products (such as recycling and reusing post-consumer components) to make sure there is as little waste and carbon impact as possible.

When should you use PVC and when you should use ABS?

When considering the material characteristics of both PVC and ABS, it seems there are very few differences between them. Both are strong, highly resistant, and cost-effective options. However, there are some key reasons why you might not choose either thermoplastic or consider an adapted version of these polymers.

Alongside their limited use for food-based applications, one of the main reasons PVC or ABS might not be suitable is that, compared to other types of plastics, they don’t have high temperature resistance. This means ABS can’t be used in direct sunlight and PVC can’t be used for applications where a continuous service temperature of more than 122°F is required.

Without controlling plastic temperature, injection pressure and speed carefully, PVC and ABS is at risk of burning, degrading or becoming too viscose to mold effectively. This means the components produced won’t possess the desired material characteristics, such as the gloss finish or high durability and strength.

Another benefit of choosing an experienced injection molding manufacturer is that they’ll be able to recommend whether PVC or ABS will be best for each specific application. With detailed knowledge of each thermoplastic and how they are best used within the injection molding production process, manufacturers such as Essentra Components can ensure that selected PVC or ABS components have all the desired performance qualities for its particular end use.