Production of PP Laminated PE Non-woven Fabric: Process and Applications in Healthcare Product information 14/09/2023

On the path of healthcare development, providing quality and safe products is crucial. One indispensable component in the medical industry is the PP laminated PE non-woven fabric, widely used in various medical applications. In this article, we will explore the process of producing PP laminated PE non-woven fabric and its significance in the healthcare field.

Creating Non-woven Fabric

Material Selection

The process begins with selecting the basic raw materials. Non-woven fabric is made from short and long fibers, which can be produced from polypropylene (PP), polyethylene (PE), or other polymers. In this case, we are discussing PP non-woven fabric.

Material Processing

PP material undergoes processing using chemical, mechanical, or thermal methods. This process creates PP fibers and prepares them for the next step in the production process.

PE Film Lamination (Polyethylene)

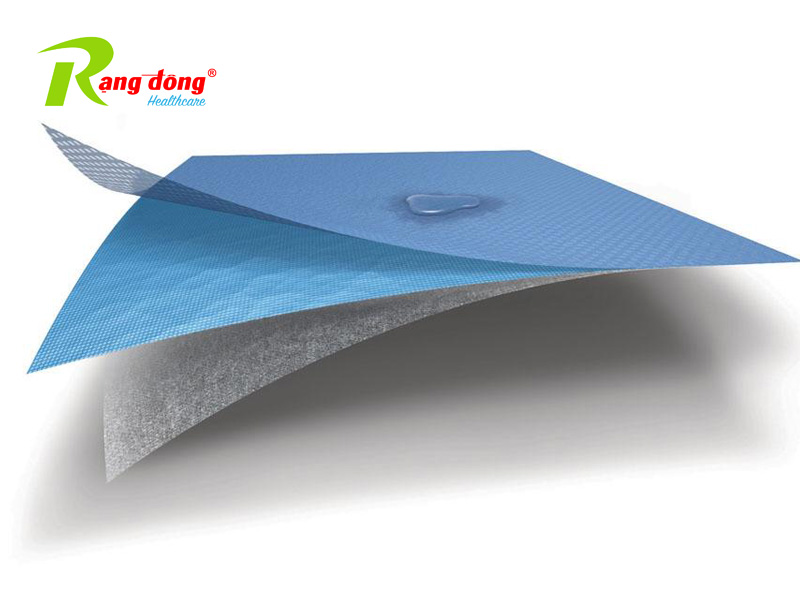

Application of Water-Resistant Layer

After obtaining PP non-woven fabric, a layer of PE film is laminated onto the fabric surface. This PE layer is responsible for imparting water resistance to the final product, a crucial feature in medical applications where contact with water and fluids is inevitable.

Laminating the Film

Application of Liquid Polymer Adhesive Layer

Next, a liquid polymer adhesive layer is applied to a previously laminated PE film layer. This film layer has been laminated with PE in the preceding step. Subsequently, this complex film layer is immediately bonded with a second complex film layer.

Drying the Product

After the two complex film layers are bonded, the product needs to be dried to remove water from the solvent. This process ensures the stability of the product and meets necessary quality standards.

In the medical industry, PP laminated PE non-woven fabric is widely used for applications such as wrapping medical products, especially in surgical and hygiene processes. Due to its waterproof properties and ability to protect against bacteria, it has become an essential part of healthcare.

In the context of improving healthcare services in Vietnam and worldwide, the market for healthcare products is expanding, leading to significant transformations. As competition among suppliers intensifies, Rang Dong Healthcare Joint Stock Company emerges with the motto “For the health of the community as a foundation.” The products are manufactured according to U.S. standards, marking a significant advancement for the healthcare industry in Vietnam.