Thin, beautiful, and convenient disposable spoon manufacturing technology Product information 16/06/2022

Disposable spoons are widely used in the F&B industry, food stalls, and takeaway beverage shops. The technology behind the production of disposable spoons has been continuously improved, resulting in thin and aesthetically pleasing products that meet food safety standards. Below is information about distinguishing disposable plastic spoons, the manufacturing process, and professional production locations.

How are disposable plastic spoons produced?

How to differentiate between ordinary and premium disposable plastic spoons?

There are many types of disposable plastic spoons available on the market. Their designs may not differ significantly. If you want to purchase affordable products, it is quite easy. However, if you want to buy premium spoons for branding purposes, you need to know how to differentiate them to avoid confusion. There are three ways to differentiate between ordinary and premium disposable plastic spoons.

Method 1: Visual Observation

This is the most common way to differentiate between products. You can observe the external packaging, such as:

- Plastic spoons packed in 100 pieces per pack

- Plastic spoons packed in 50 pieces per pack

- Plastic spoons packed individually

Plastic spoons that are packed in large quantities per pack, such as 100 or 50 pieces, are usually more affordable and intended for the general market. On the other hand, plastic spoons packed individually are often of higher quality and designed for premium markets, branded food and beverage establishments. This observation is based on surveys conducted at disposable plasticware retail locations. However, it may not always be entirely accurate.

Another way to visually observe is to examine the surface of the product. Premium disposable plastic spoons have a shiny, even-colored surface with delicate lines. Some product lines may even feature the manufacturer’s brand logo engraved on the back of the spoon.

Packaging of Plastic Spoons

Method 2: Sensory Perception of Plastic Spoons

By holding the product in your hand, you can distinguish between high-quality disposable plastic spoons and ordinary products. High-quality plastic spoons are thin and lightweight, with a rigid handle that provides a firm grip. They are flexible and resistant to deformation when bent.

When touching the curves of the spoon, they feel smooth and glossy, without any roughness. The rim of the spoon is smooth and polished, with a shiny upper surface and a slightly textured lower surface. The edges of the handle are even, creating a sense of balance. The transition point between the handle and the spoon’s food-holding part is designed to be soft, with a harmonious and elegant transition.

Method 3: User Experience

This method determines the value of disposable plastic spoons. High-quality disposable plastic spoons are individually packaged, emphasizing personalization and ensuring food safety whether used on-site or for delivery/takeout. The user will personally tear the spoon’s seal.

The smooth and glossy surface minimizes food residue. The spoon provides a secure grip, allowing for confident and spill-free scooping. It is convenient for various dessert options. The smooth and well-designed curved rim facilitates easy and comfortable eating, without causing any discomfort or harm to the user.

Brand-identifying plastic spoons

Thin and Beautiful Disposable Spoon Production by Injection Molding Technology

Of course, for high-quality disposable plastic spoons, the manufacturing process requires modern technology and strict quality standards. The production process ensures food safety and hygiene. Disposable spoons are manufactured using injection molding technology, which is one of the techniques for producing thin plastic utensils with excellent quality and automated operation.

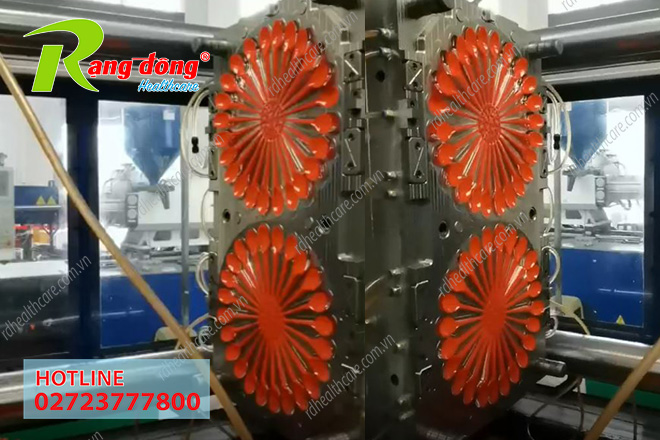

The plastic materials and additives are placed into a machine where they are melted and mixed together. The molten material is then injected into molds to create the desired shape of the product. Afterward, the products are removed from the molds by a robotic arm and undergo sorting and classification according to the standards. The molds play a crucial role in the injection molding process as they determine the shape of the final products. Each product has its own dedicated mold that corresponds to its specific design requirements.

The injection molding technology operates entirely in an automated manner. Once the machine starts running, only one person is needed to inspect the finished products to ensure quality. Due to the closed-loop production process, which includes material mixing, plastic injection, and cooling, the resulting products have consistent quality. In addition to producing disposable plastic spoons, the injection molding technology can be used to manufacture various other products based on specific orders.

Injection Molding Technology for Disposable Spoon Production at Rang Dong HealthCare

Modern Injection Molding Facility for Disposable Spoon Production

Injection molding technology is commonly used for the production of medical plastic products. However, it can also be utilized to manufacture various household plastic items, including disposable plastic spoons. At Rang Dong HealthCare, a company specialized in medical plastic production, we employ state-of-the-art injection molding technology to produce disposable plastic spoons and other plastic products. As a member of the Rang Dong Plastic Group, with over 60 years of establishment and development, we prioritize the quality of our products and services.

Production of Disposable Plastic Spoons Based on Existing Molds

The mold used in injection molding is a specialized mold custom-made for each type of product. For single-use plastic spoons, Rang Dong HealthCare has standard molds specifically designed for the premium product line. The production process ensures a consistent batch of products in terms of color and size. As a medical manufacturing facility, product quality is our top priority, meeting strict standards for safety and hygiene.

The company has a standardized packaging system in place. Each spoon is individually packaged, with the company’s brand identification printed on the back groove, ensuring clear origin and source of the product. Using these available molds, the company can manufacture various types of single-use plastic spoons in different colors according to the requirements of our customer partners.

Large-Scale Production of Custom-Ordered Products

Modern Technology and a Large-Scale Manufacturing Facility. Rang Dong HealthCare warmly welcomes partnerships with customers to jointly research and develop new products. We specialize in the large-scale production of custom-ordered products, including new mold designs using injection molding technology and other technologies owned by our company.

When collaborating with Rang Dong HealthCare, you can have complete trust. We are currently undergoing digital transformation, implementing strict quality management systems and product inspections that have been highly regarded by reputable organizations. Furthermore, our customer partnership policies prioritize the protection of your rights and interests. We promptly and efficiently address any issues regarding products and service quality according to ISO 9001:2018 standards.

For detailed information on the production of single-use plastic spoons and other plastic products using injection molding technology, please contact Rang Dong HealthCare for personalized consultation.

Rang Dong HealthCare Joint Stock Company

“Your Health, Our Mission”

- Factory Address: Lots G4-G8, Street No. 8, Tan Do Industrial Zone, Long An Province.

- Hotline: 0272 3777 800

Tags: công nghệ ép phun, muỗng nhựa dùng 1 lần, muỗng dùng 1 lần, sản xuất muỗng nhựa, sản xuất muỗng nhựa dùng 1 lần, sản xuất muỗng nhựa giá rẻ, công ty sản xuất muỗng dùng 1 lần, xưởng sản xuất muỗng nhựa dùng 1 lần, nhà máy sản xuất muỗng nhựa dùng 1 lần