Non-Woven PP PE Composite Fabric: Promising Future Product information 01/11/2023

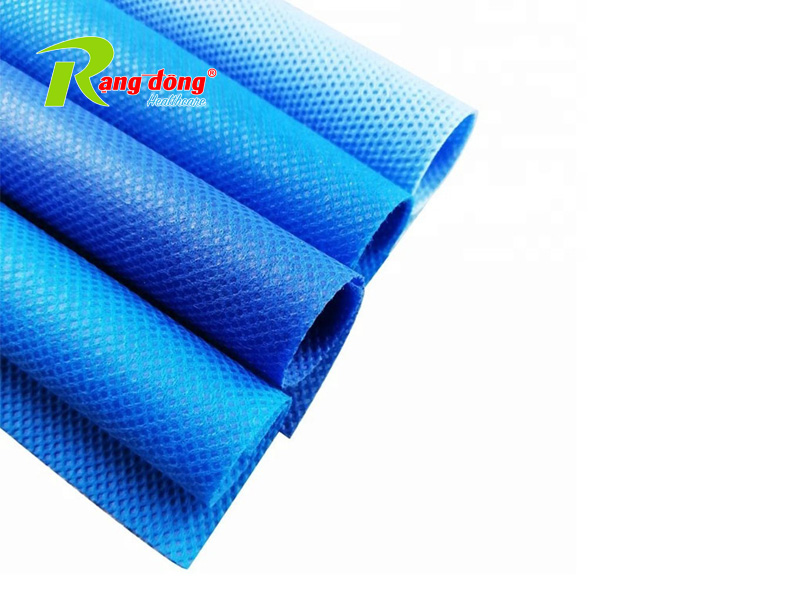

Non-woven PP PE composite fabric (Polypropylene bonded with Polyethylene) is a versatile material with strong potential for future development. This article will present the prospects and applications of this material in industries such as healthcare, construction, and packaging. Let’s explore the progress and opportunities that non-woven PP PE composite fabric brings.

Healthcare: Significant Development

Non-woven PP PE composite fabric has seen significant development in the healthcare sector. This material has many important applications in the production of medical products. With the impact of the COVID-19 pandemic, opportunities in this field have been greatly accelerated.

Applications in Healthcare

Non-woven PP PE composite fabric is used to manufacture high-quality medical face masks, surgical gowns, and many other products. Here are some highlights of its applications in healthcare:

- Medical Face Masks: Non-woven PP PE composite fabric is used to produce high-quality medical face masks. These masks have the effective ability to filter bacteria and viruses, protecting users from the risk of infection.

- Surgical Gowns: In surgeries, gowns must ensure safety and hygiene. Non-woven PP PE composite fabric provides waterproof and protective features, while remaining comfortable for the wearer.

- Medical Product Packaging: Additionally, this material is used in the packaging of medical products such as consumables, medicines, and medical equipment.

Non-woven PP PE composite fabric has made a significant contribution to the healthcare industry by providing safe and effective products. With increasing demand for medical products, this market promises many opportunities for development.

Construction: Soundproofing, Insulation, and Waterproofing

In the construction industry, non-woven PP PE composite fabric also has many important applications. This material has soundproofing, insulation, and waterproofing capabilities, creating a better living and working environment.

Soundproofing and Insulation

Non-woven PP PE composite fabric is used for soundproofing and insulating construction projects. It helps reduce noise and regulates temperature in buildings, making living and working spaces more comfortable.

Waterproofing

The waterproofing applications of non-woven PP PE composite fabric make it an ideal choice for preventing water and moisture intrusion in construction projects. This is especially crucial in protecting infrastructure and assets.

Packaging: Environmentally Friendly

In the packaging industry, non-woven PP PE composite fabric has garnered significant attention. This material is considered an environmentally friendly solution and is widely used in the production of various types of packaging.

Applications in Packaging

Non-woven PP PE composite fabric is used to manufacture bags, shopping bags, and other types of packaging. These applications are highly regarded for the following reasons:

- Environmentally Friendly: This material not only ensures environmental friendliness but also has the ability to be reused, reducing plastic waste.

- Durable Products: Packaging products made from non-woven PP PE composite fabric are known for their durability, protecting the contents and reducing the risk of damage.

- Flexibility: This material offers design versatility and printing capabilities, creating unique packaging products.

Investment and Research Are Key

Although non-woven PP PE composite fabric has many prospects and potential applications, to make the most of these opportunities, businesses and manufacturers need to invest in technology, research, and development.

Ensuring product quality, optimizing the production process, and staying ahead of new market trends are essential for success. Additionally, maintaining the sustainability and environmental friendliness of the product plays a vital role in attracting customer interest.

Non-woven PP PE composite fabric is a versatile material with significant potential for future development. Widely used in healthcare, construction, and packaging industries, this material makes a substantial contribution by providing efficient products and solutions. However, for success, businesses need to invest in research and development to ensure quality and environmental friendliness.