Introduction to PP Coated PE Non-Woven Fabric Product information 20/09/2023

In the context of the healthcare industry, healthcare services in Vietnam and around the world are continually improving. As a result, the market for healthcare products is expanding, leading to significant transformations and intense competition among providers. Hence, Rang Dong Healthcare Joint Stock Company was established with the motto “for the health of the community as a foundation.” The products adhere to US standards, marking a crucial step forward for the healthcare industry in Vietnam.

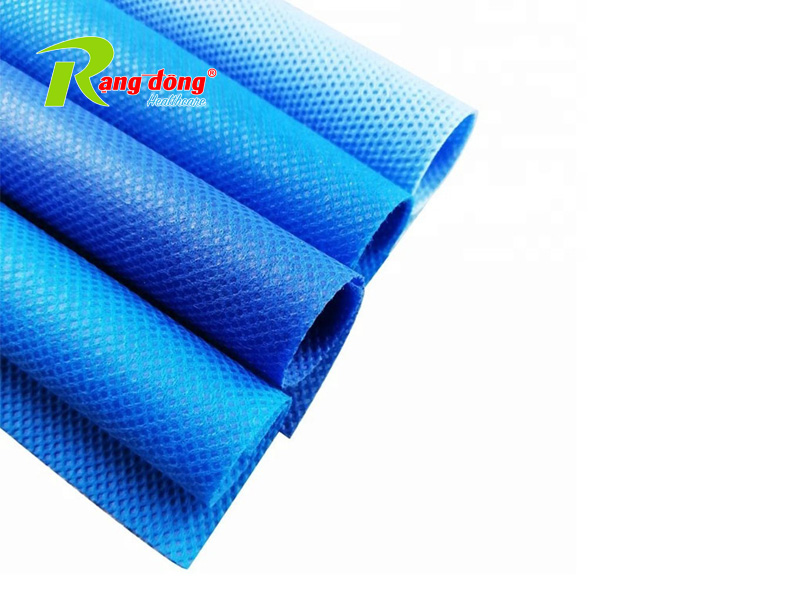

PE Coated Non-Woven Fabric: Primary Component in the Healthcare Sector

PE Coated Non-Woven Fabric is a versatile material widely used in various fields, from healthcare to industry and consumer goods. Polyethylene (PE) is laminated onto non-woven fabric to provide waterproof, moisture-resistant, and barrier properties against liquids, bacteria, and viruses. The PE layer helps prevent the infiltration of liquids, ensuring safety and hygiene in medical applications.

- Waterproof PE Coated Non-Woven Fabric

Waterproof PE Coated Non-Woven Fabric is extensively used in construction and industry to create waterproof materials for different projects and products. This is crucial in safeguarding infrastructure and medical equipment from water and other liquids.

- UV-Resistant PE Coated Non-Woven Fabric

Another application is protecting against ultraviolet (UV) rays. This type of fabric is coated with a PE layer that can resist harmful UV rays from sunlight. This makes it an ideal choice for products that need protection from UV rays, such as medical protective clothing and UV-blocking screens.

- Dust-Resistant PE Coated Non-Woven Fabric

PE Coated Non-Woven Fabric also finds application in preventing dust and small particles from entering our living and working spaces. The tight non-woven structure and the waterproof PE layer make this fabric effective in blocking dust. This is particularly important in healthcare environments where hygiene is a top priority.

The Combination of Non-Woven Fabric and PE Layer

Combining non-woven fabric with a PE layer allows the creation of high-quality products with waterproof, dust-resistant, UV-resistant, and many other features. This is valuable not only in the healthcare industry but also in various other fields.

Below are some common applications of this product:

In Healthcare:

- Medical Packaging: PE Coated Non-Woven Fabric is often used to package and protect medical products such as medical masks, surgical instrument packaging, and more.

- Healthcare Protective Gear: Medical protective clothing and medical raincoats are commonly manufactured from PE Coated Non-Woven Fabric to ensure quality and safety.

In Industry:

- Waterproofing for Construction Projects: PE Coated Non-Woven Fabric is used to create waterproof layers for construction projects like mines, factories, and high-rise buildings.

- Industrial Protective Gear: In the industrial environment, products like industrial raincoats and waterproof packaging are often made from PE Coated Non-Woven Fabric.

With the continuous development of the healthcare and industrial sectors, the combination of non-woven fabric and PE has brought about significant benefits. The product’s waterproofing, dust resistance, UV resistance, and safety features contribute positively to improving the quality of life and safeguarding human health.