Injection Molding Process and Technology in the Production of Plastic Household Items Product information 09/09/2023

If you are exploring the injection molding process and technology in the production of plastic household items, you have come to the right place. In this article, we will delve deeper into this technology, how it works, and its common applications in the industry.

How is Single-Use Plastic Spoon Manufactured?

Injection Molding: Exploring Plastic Manufacturing Technology

Injection molding is a manufacturing technology that produces products by injecting molten material into a mold. This process can be applied to various materials, including metals, glass, elastic materials, and, of course, plastic. Let’s explore this process further:

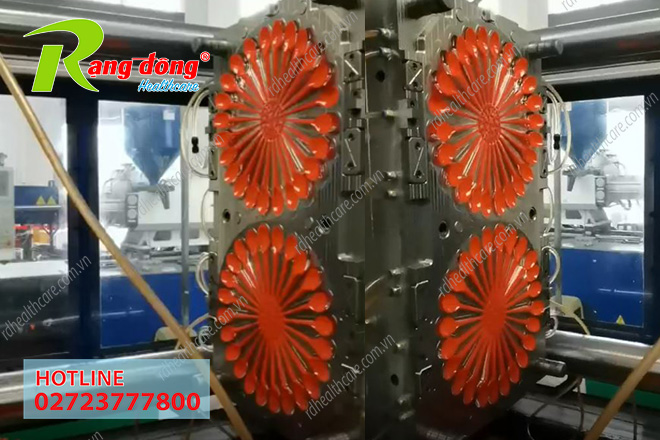

Injection Molding Technology in the Production of Single-Use Spoons at Rang Dong HealthCare

- Prepare the Material

Before starting the injection molding process, the material needs to be prepared. Typically, plastic material is placed in a hot barrel and then uniformly mixed using a screw system.

- Inject Material into the Mold

Once the material is ready, it will be injected into the mold. This process creates our final product.

- Cooling and Solidification

After the material is injected into the mold, it will be cooled and solidified into the shape of the mold.

- Mold Manufacturing

The molds necessary for the injection molding process are manufactured by mold makers. Usually, mold-making materials include metals such as steel or aluminum. The molds are then precision processed to achieve the required shape.

Applications of Injection Molding Technology

Injection molding technology is widely used in various industrial fields, especially in the plastic manufacturing industry. Below are some common applications:

- Production of Plastic Household Items

Injection molding is an ideal method for producing large objects with the same mass, such as plastic household items. Products like chairs, tables, and many other household items are manufactured using this technology.

- Manufacturing in the Packaging Industry

Additionally, injection molding technology is applied in the production of packaging, bottle caps, and related products. This helps create high-quality and reliable packaging products.

- Automotive Components

This technology is also used in the production of automotive parts and other components. These products must meet high-quality standards to ensure the safety and performance of vehicles.

- Medical Industry

Finally, injection molding technology is applied in the production of essential medical equipment. This ensures that medical products meet strict quality and safety requirements.

Key Parameters in Injection Molding Technology

When discussing injection molding technology, there are several key parameters that you need to understand:

- Injection Volume

Each type of plastic molding machine will have a specific injection volume. This depends on the operating conditions of the machine and the final product you want to create.

- Injection Speed

Injection speed is a crucial factor affecting the shape of the product. It needs to be adjusted correctly to ensure a perfect product.

- Injection Pressure

Injection pressure is a decisive factor in the injection molding process. This also needs to be adjusted appropriately based on the mold structure and material properties.

- Mold Area

The mold area is a basic parameter determining the size of the product. It affects the clamping force of the mold and the overall structure of the product.

As you can see, injection molding technology is an essential part of the manufacturing industry and has many wide-ranging applications. It has changed the way we produce and consume everyday plastic products. If you want to learn more about this process or how it works in a specific industry, feel free to contact us.